Spiralbanding BOP Testing

Test Results with Variable Rams

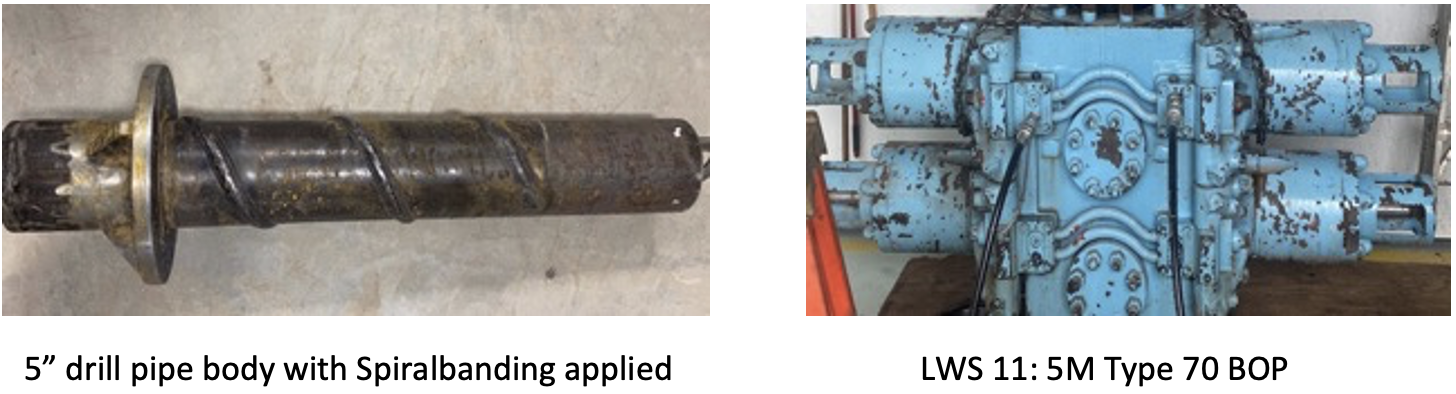

Well pressure control is always something that needs to be considered when drilling oil and gas wells. When formation fluid begins to enter the well bore during drilling operations in an uncontrolled manner, the Blow Out Preventer (BOP) needs to be closed before formation fluids reach the surface. For testing the interaction between Spiralbanded drill pipe and BOP equipment, variable pipe rams were used to compensate for the standoff of the Spiralbanding.

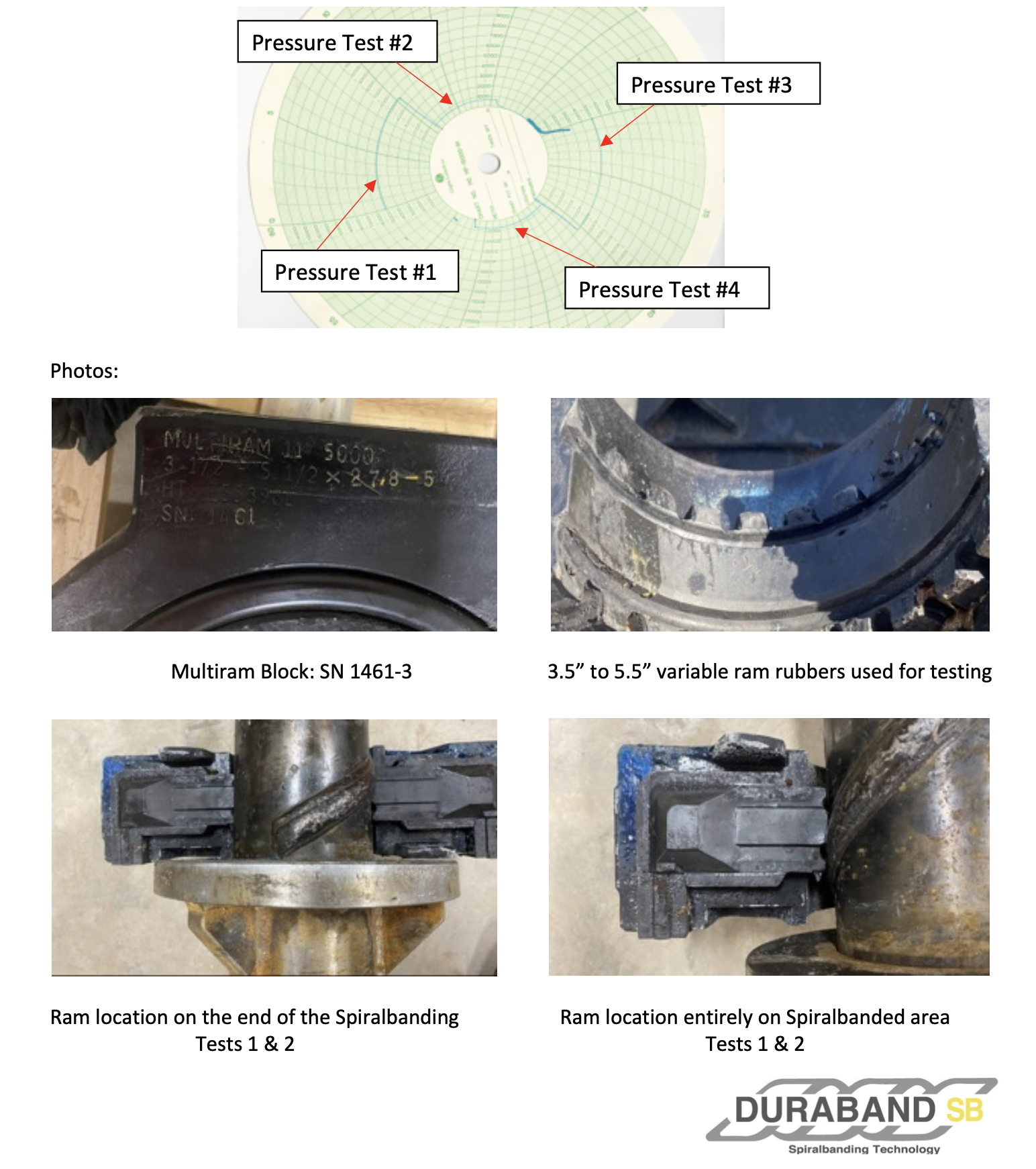

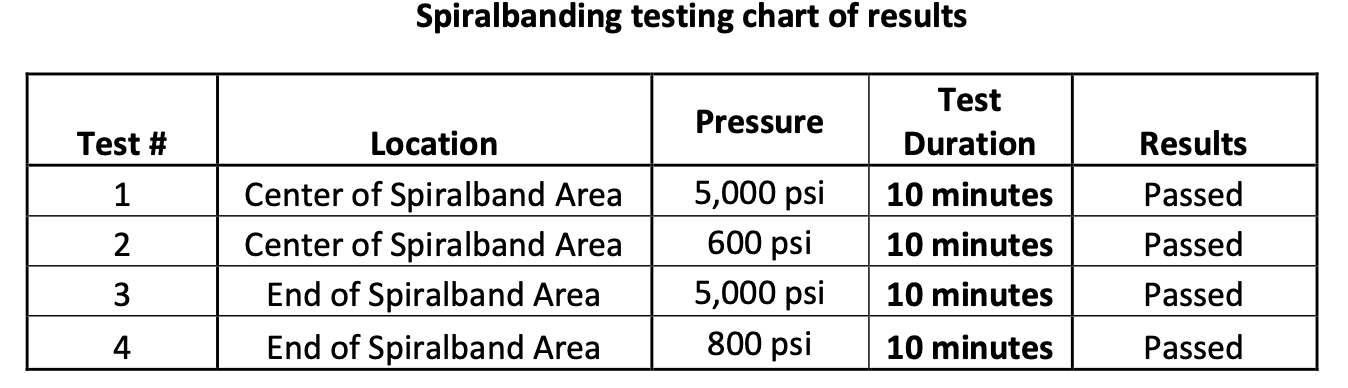

Four separate pressure tests were performed on a Spiralbanded test joint. The table below outlines the location of the tests, the test pressures, test duration, along with the results. For Tests 1 and 3, the pressure was stabilized at 5,000 psi for 10 minutes then the pressure was released to 0 psi. Tests 2 and 4 were re-pressurized to 600 psi and 800 psi respectively, for a low-pressure cycle. Two tests were performed on the center of the Spiralbanded configuration and the remaining two tests were performed at the end of the Spiralbanded area to make sure pressure could be maintained anywhere within the Spiralbanded region.

Results:

After completing the four tests, it was shown that the 5” drill pipe sample with Spiralbanding applied to the OD can have variable rams successfully close and hold pressure without any pressure drop.

The chart below shows the recorded pressures indicating no pressure drop.